LH-1510+ is a flexible, efficient and easy-to-use semi-automatic liquid workstation, which can be widely used in third-party medical laboratories, blood stations, hospitals, Centers for Disease Control (CDC) , research institutes and other fields.

nXYZ tri-axial independent movement realizes perfect replication of 384-well plates, breaking the traditional method of overturn by hands on the semi-automatic workstation. LH-1510+ demonstrates the "fully automatic" advantages of semi-automatic workstations.

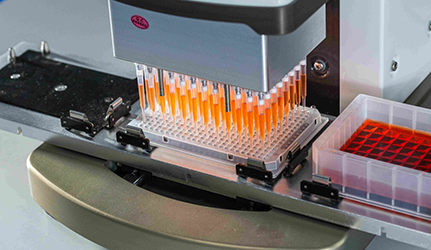

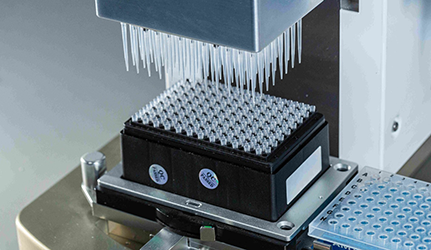

n96-channel pipetting head can do suction and dispense with a column (8 channels), to distribute different reagents to every columns of 96-well plate.

nThe instrument is 47cm×37cm×60cm (length × width × height), which can be placed in a super clean bench or a biosafety cabinet to realize aseptic operation treatment of reagents or samples.

There are 1000 µL, 250µL and 70µL 96-channels pipetting heads to achieve the pipetting volume range of 0.5µL-1000 µL, which can meet the needs of different applications.

According to different applications, it can be combined with "one machine with multiple pipette heads". Customers can change the pipetting heads by themselves according to the simple installation guide, which is convenient to operate.

In order to meet the needs of different customers, software versions for Windows and Android systems have been developed. The software has friendly interactive interface, easy to operate and learn. The program is built with several template, can be directly open and use. Also it can be edited flexibly for liquid separation, dilution, orifice replication and other functions.

The layout of the three bases meets the work flow of "Tips, original plate and target plate", which not only simplifies the worktable, but also speeds up the operation process.

50µL Tips is designed according to the structural diagram of pipetting Barrel. Through customized mold development, repeated optimization and strict QC, they are cost-effective and quality assurance , greatly reducing the operating cost of the equipment.

Dimensions (length × width × height) | 47cm×37cm×60cm |

Weight | About 30 Kg |

Deck Capacity | 3 |

Power supply | AC220V,50Hz,350W |

Three types of 96-channel pipetting heads | 70μL、250μL、1000μL |

Pipetting volume range | 0.5μL -1000μL |

Types of Pipetting head | Pipetting volume(μL) | Pipetting Accuracy(≤CV%) | Pipetting precision(±%) |

70μL | 1 | 5.0 | 10.0 |

5 | 3.0 | 6.0 | |

25 | 2.0 | 4.0 | |

50 | 1.0 | 2.0 | |

250μL | 10 | 3.0 | 6.0 |

50 | 1.0 | 2.0 | |

150 | 0.5 | 1.5 | |

1000μL | 100 | 0.5 | 1.5 |

500 | 0.3 | 1.0 | |

900 | 0.3 | 1.0 |